Technologies

FERRMONT is a major supplier and producer of technologies for wastewater treatment plants.

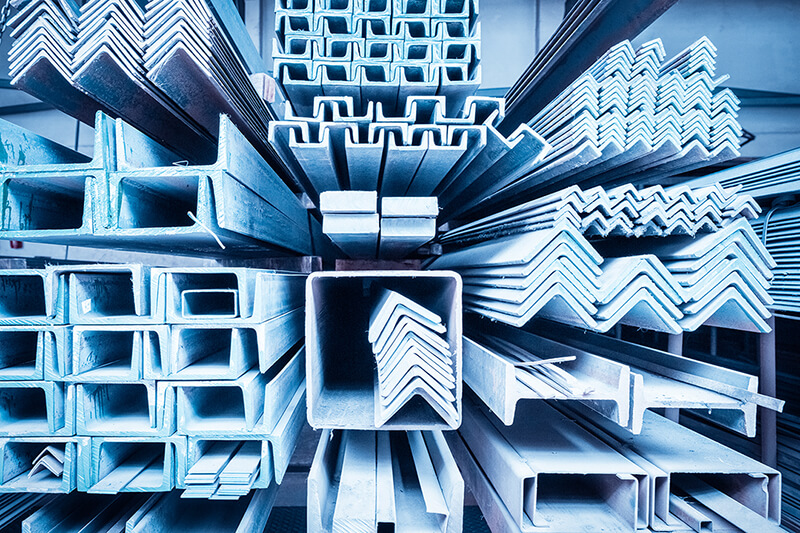

Our own production ensures the flexibility that is necessary for the supply of turnkey solutions. The main portfolio consists of the supply of technological equipment for wastewater treatment, steel, hot-dip galvanized structures, complete plastic aeration systems and machinery, including assembly..

Aeration systems

The efficiency of the transfer of oxygen to the activation mixture depends on the type and quality of the diffusers, i.e. how much oxygen actually reaches bacteria and other microorganisms from the supplied air. The higher the quality and efficiency of the diffusers, the smaller size of the blower is required and thus the consumption of electricity, so the correct selection of diffusers is crucial for the operation of the cleaning plant. There are diffusers of several types and shapes (disc, plate, tubular, with a silicone membrane, ceramic…), the exact type is always optimally designed for each installation.

FERRMONT supplies diffusers from renowned manufacturers (Rehau, Sanitaire, Nopon, etc.), which are among the highest quality and most effective on the market. FERRMONT also manufactures its own Ferox tubular diffusers with fine-bubble silicone membrane from Rehau. These diffusers are ideal for the reconstruction of aeration systems in wastewater plants, where diffusers of the previous generation ČOVOX 1000 were used, because they allow the replacement of old diffusers with new ones without the need to replace the entire distribution pipeline.

Steel constructions

Gas fields

Ferrmont has extensive experience in the design of gas management, which is used in many WWTPs that we have implemented. First, the gas is accumulated in gas reservoirs in order to eliminate the uneven production of biogas during the day. The gas tanks realized by us are dry double-membrane gas tanks, which, thanks to their modern design, enable constant condition monitoring, are not subject to corrosion, create operating pressure and are significantly safe.